Bullets:

China is moving to a lean manufacturing model to mass produce space vehicles.

Inside China / Business is a reader-supported publication. To receive new posts and support my work, consider becoming a free or paid subscriber.

Chinese carmakers now dominate automobile production, bringing together vast capital and talent pools, supply chain monopolies, and “pull” manufacturing techniques.

By employing the same processes that led to China’s success in the car industry, Chinese engineers hope to quickly surge past SpaceX, with hundreds of orbital launches annually.

For the YouTube video for this report, please follow this link:

Report:

Good morning.

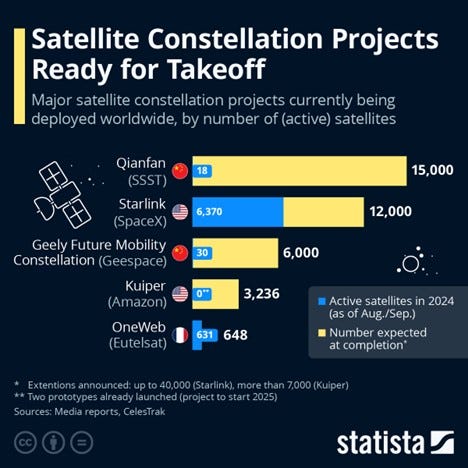

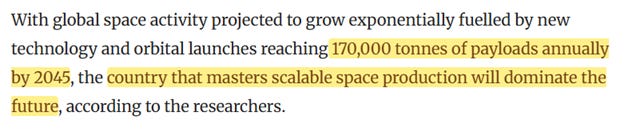

The Space Race is a strange one, because on the US side it is represented by just a handful of private companies, SpaceX, most notably. And the race over the next decades will be decided by who can put the most rockets into the sky, faster. Insiders forecast that in 20 years, the industry worldwide will be sending up 170,000 tons a year. China recently hit another record for their space launches, with 70 orbital launches for the year.

China has big ambitions in space, with several global systems planned. The headlines here refer to a new approach to manufacturing rockets, at scale, and faster. Here is the main problem facing rocket designers: each rocket needs to be designed differently, and built differently, depending on who needs it. A rocket for a defense contractor who needs it for a big satellite, and developed in extreme secrecy, is different from the demands of the National Weather Service, and different again from communications satellites, and far different from the rockets SpaceX builds to put up dozens of satellites at the same time. Put human beings on the things, with life support functions, and those rockets are completely different again.

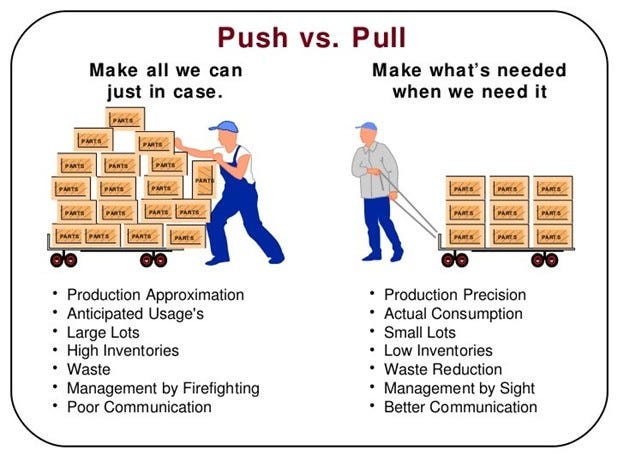

What the Chinese here hope to do, is stop making them all differently, and customized, and instead build them mostly the same. Until very recently, manufacturers used a “push system”. They would design a product, forecast how much of it they could sell in the market, build the products, then get to work on selling them. They pushed the products through their factories, then pushed them into the market.

Toyota was the company that flipped around and instead employed a “pull system”. It was the customers who would pull products through. Production would be based on actual demand, instead of forecasted demand. Waste is reduced, along with inventory holding costs, and lean manufacturing was born:

What is required for it to work in the space industry, is a very high degree of standardization for each rocket, but with enough final demand for each rocket type that it keeps everyone busy. The industry is past the stage of whether the rockets can be built—they can—now the strategy is to select a handful of designs that can be mass-produced, depending on the customers for each one.

Thinking of Toyota and the carmakers again, building small sedans up to SUV’s and small buses. The buyer may customize them in a few instances—exterior color, for example, or a high-end entertainment package. But almost everything about that particular vehicle is the same with every single other one.

Everything about this plays to China’s strengths today in manufacturing. Once their engineers decide on a design, the Chinese industrial sector gets busy on locking up the supply chains and talent pools, and then sets up the assembly lines that are building dozens of them now, and thousands over time. China’s space industry here is saying that these rockets are much more alike, than they are different–and that there is future demand for each different type. What’s more, they’re positioning themselves to be the global standard for each model type.

Toyota is the company used, because the story of Toyota is the one most familiar to manufacturing engineers and managers who execute production strategy. Toyota was the pioneer of the “pull” process in factory operations.

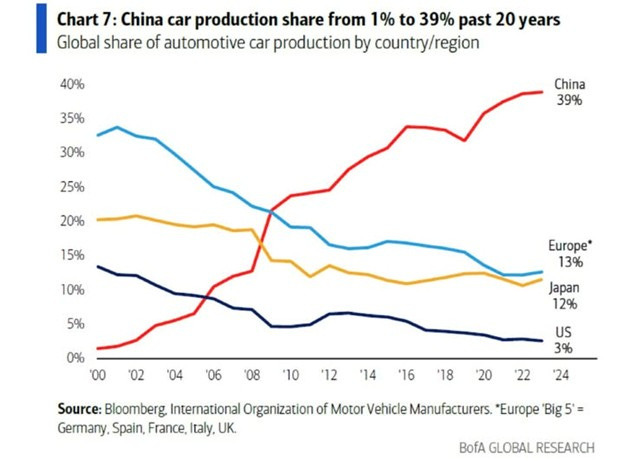

But it’s Chinese car factories that took it to another level. Toyota was hamstrung in its early days by Japan’s position after the war—the company had no money, all the supply chains for automaking went through Detroit, and they didn’t even have much experience building cars at all. Those are not features of China today:

Capacity and capital are abundant, and all the supply chains run through China. And in a mere decade or so China went from building zero cars for export to world markets, to having our own experts wondering how long before China is building all of them.

That’s why that little blurb right there is so important, if China does the same thing for space vehicles that they’ve just done for the vehicles down here.

Be Good.

Resources and links:

Satellite Constellation Projects Ready for Takeoff

https://www.statista.com/chart/33246/satellite-constellation-projects/

Chinese company CAS Space takes steps toward 1st launch of reusable rocket

https://www.space.com/china-cas-space-reusable-rocket-progress

Substack, When Every Car Is Made in China

https://substack.com/home/post/p-144365194

China breaks annual launch record with VLEO Chutian and Shiyan technology test launches

Space pull system: China’s industrial revolution to make rockets and satellites like cars

Stock Sharks: From 1% to 39% global share of car production in 20 years

Inside China / Business is a reader-supported publication. To receive new posts and support my work, consider becoming a free or paid subscriber.

From Inside China / Business via this RSS feed