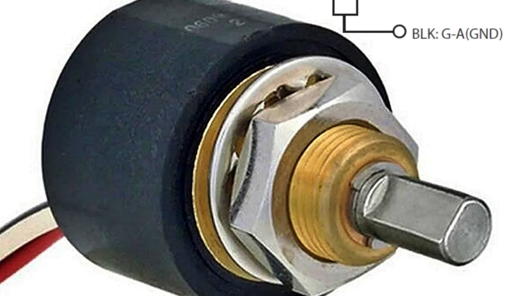

Ever tear open a potentiometer? If you haven’t, you can still probably guess what’s inside. A streak of resistive material with some kind of contact that moves across it as you rotate the shaft, right? Usually, you’d be right, but [T. K. Hareedran] writes about a different kind of pot: ones that use magnetic sensing.

Why mess with something simple? Simplicity has its price. Traditional units may not be very accurate, can be prone to temperature and contamination effects, and the contact will eventually wear out the resistive strip inside. However, we were a little curious about how a magnetic potentiometer could offer a resistive output. The answer? It doesn’t.

Really, these would be better described as rotary encoders with a voltage output. They aren’t really potentiometers. The SK22B mentioned in the article, for example, requires a 5 V input and outputs somewhere between 10% and 90% of that voltage on the ersatz wiper pin.

That makes the devices much easier to puzzle out. The linearity of a device like that is better than a real pot, and, of course, the life expectancy is greatly increased. On the other hand, we’d rather get one with quadrature or I2C output and read it digitally, but if you need a voltage, these devices are certainly an option.

[T. K.] goes on to show how he fabricated his own non-contact sensor using photosensors and a gray-coded wheel with a single track. You do need to be careful about where you position the sensors, though.

Could you make a real non-contact resistive pot? Seems like you could get close with an FET output stage, but it wouldn’t be as generally applicable as a good old-fashioned smear of carbon. If you have a better idea, drop it in the comments or build it and give us a tip.

Want a 20A-capable device? Build it. Want to see how we like to read encoders?

From Blog – Hackaday via this RSS feed